Industrial Separation Solutions

Basket & Decanter Centrifuges

Industrial Separation Solutions

Basket & Decanter Centrifuges

Industrial Centrifuge Solutions:

Solid–Liquid Separation

Solid–Liquid Separation

Discover reliable basket and decanter centrifuges designed for effective solid–liquid separation and slurry concentration. Our centrifuge systems support a wide range of applications in food processing, pharmaceuticals, palm oil, chemical production, recycling, and wastewater treatment.

At PS Mechanical Supply & Services, we supply high-performance centrifuge solutions that help industries achieve cleaner output, stable operation, higher efficiency, and reduced costs. When required, solid washing can also be integrated to improve product quality. We provide recommendations based on your process needs to ensure you receive the most suitable centrifuge for your production requirements.

Centrifugal filtration separation & Centrifugal sedimentation separation

Centrifugal separation can be divided into Centrifugal filtration separation & Centrifugal sedimentation separation

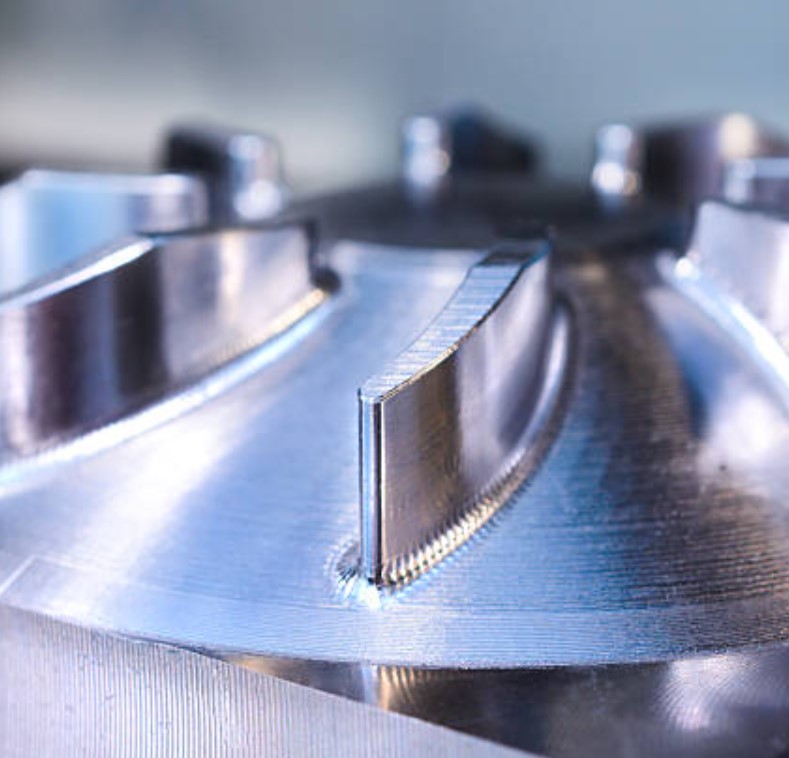

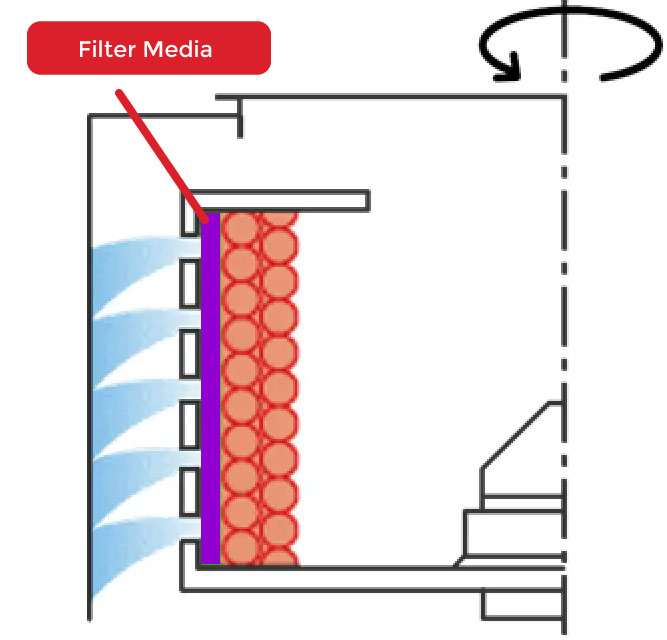

Centrifugal filtration separation

Lower solid moisture levels can be achieved through efficient centrifugal filtration separation.

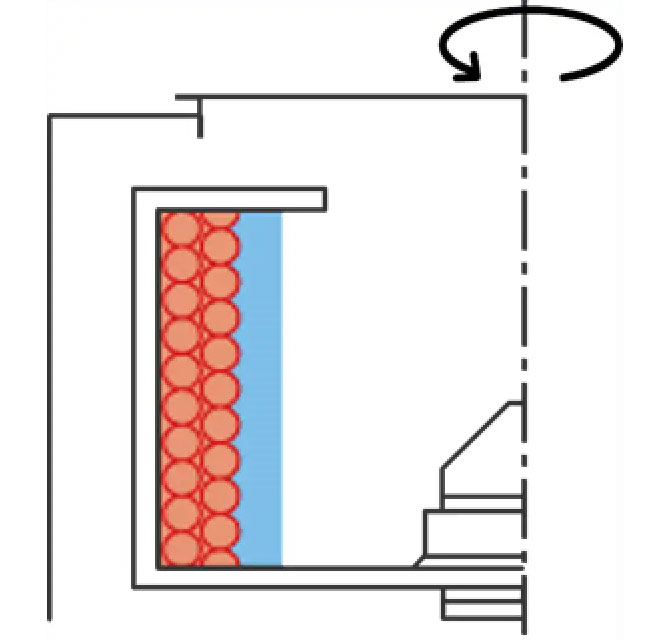

Centrifugal sedimentation separation

Suitable for fine particles that cannot be captured with filter media, and helps reduce running costs since no filter media is required.

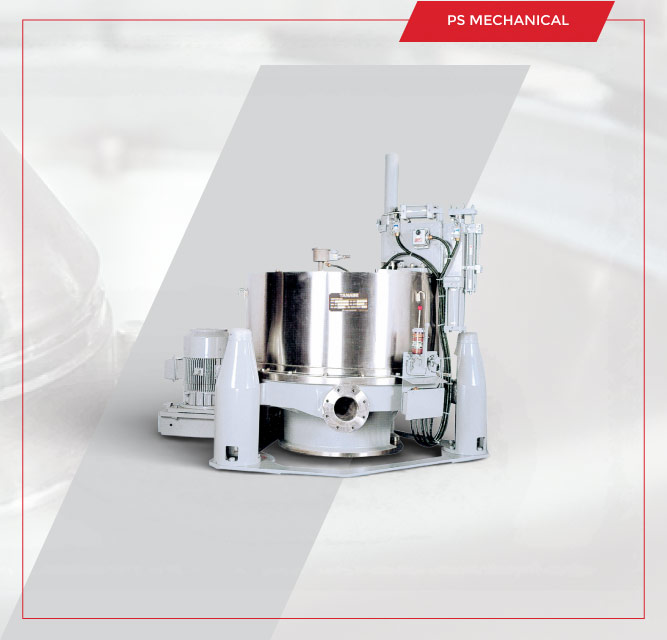

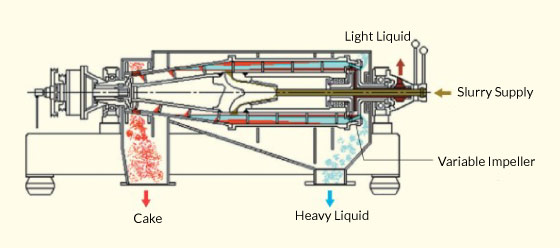

Decanter Centrifuge: 2-Phase & 3-Phase Separation

Our Decanter Centrifuges are engineered for flexibility and performance, available in both 2-phase and 3-phase models. Each system is tested to ensure the best fit for your specific application.

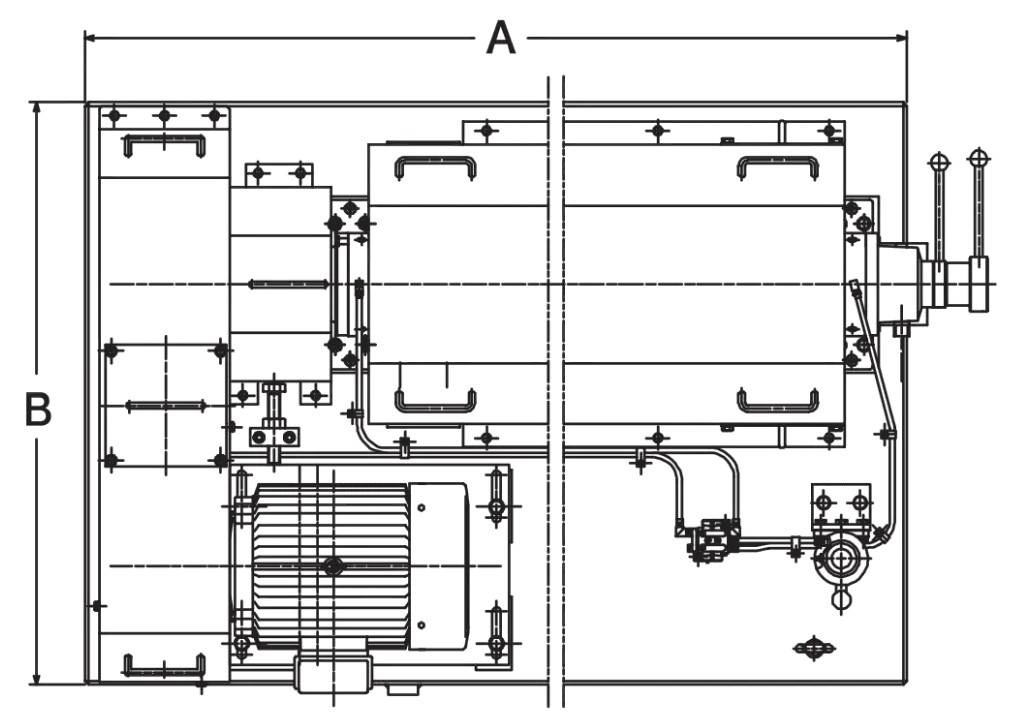

Exterior Dimensions:-

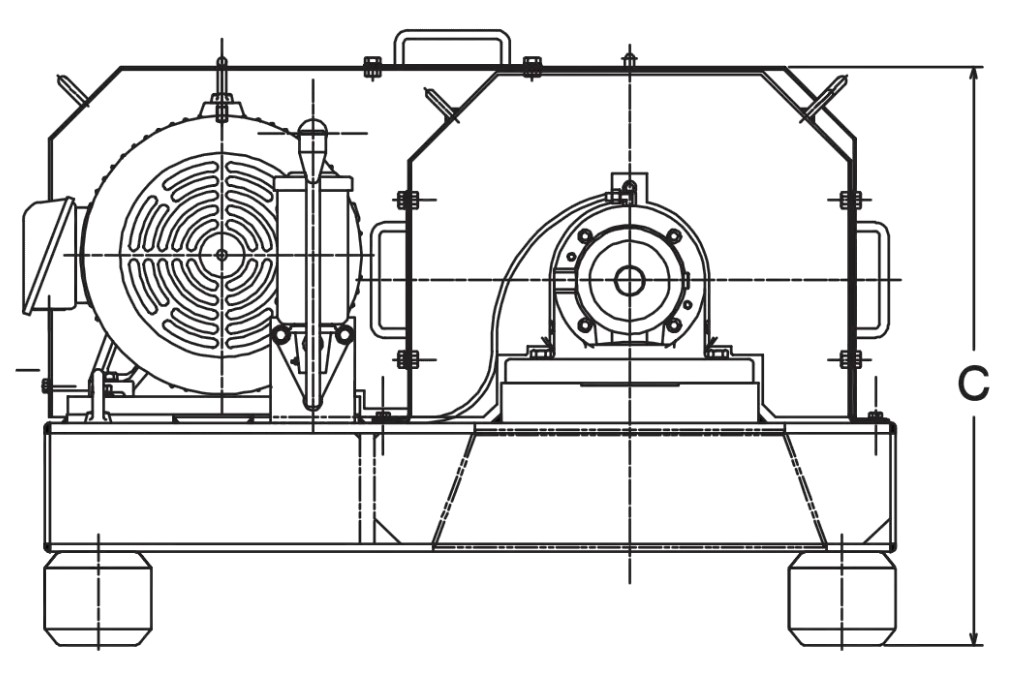

Cross Section

Technical Specifications

Speed Range: 3,000 – 6,000 rpm (depending on model)

Capacity: 0.2 m³/h (small-scale) up to 45 m³/h (large-scale)

Power: 2.2 kW to 90 kW

Size & Weight: From compact 290 kg units to heavy-duty 12,000 kg models

| Model | Max Rotational Speed (min-1) | Centrifugal Force (G) | Processing Capacity (m³/h) | Motor Power (kW) | Approx. Weight (kg) | Dimensions (mm) L x W x H |

|---|---|---|---|---|---|---|

| Z18 | 5000 | 2500 | 0.2 – 1 | 2.2 – 3.7 | 290 | 810 x 740 x 540 |

| Z1L | 6000 | 4600 | 1 – 2 | 5.5 – 7.5 | 700 | 1355 x 960 x 655 |

| Z1LL | 5000 | 3200 | 2 – 4 | 7.5 – 11 | 950 | 1600 x 960 x 655 |

| Z2L | 4200 | 3160 | 3 – 5 | 11 – 15 | 1500 | 1900 x 1300 x 930 |

| Z32 | 5000 | 4400 | 3 – 5 | 11 – 15 | 2000 | 2000 x 1300 x 930 |

| Z22L | 4200 | 3160 | 5 – 7 | 15 – 18.5 | 1700 | 2285 x 1300 x 930 |

| Z23L | 4200 | 3160 | 5 – 7 | 15 – 18.5 | 2300 | 2350 x 1300 x 930 |

| Z3L | 4000 | 3700 | 7 – 10 | 18.5 – 22 | 3000 | 2250 x 1540 x 1050 |

| Z3LL | 3700 | 3200 | 10 – 15 | 22 – 30 | 3300 | 2760 x 1540 x 1050 |

| Z53 | 3000 | 2600 | 15 – 20 | 37 – 55 | 6500 | 3450 x 1700 x 1310 |

| Z5L | 3000 | 3100 | 20 – 30 | 45 – 75 | 8300 | 3445 x 2050 x 1610 |

| Z5LL | 3000 | 3100 | 30 – 45 | 55 – 90 | 12000 | 4065 x 2200 x 1670 |

Why Choose Our Decanter Centrifuges?

Suitable for the following industry applications:

Palm Oil & Edible Oil Processing

Chemical & Pharmaceutical

Food & Beverage Manufacturing

Recycling & Environmental

Decanter Centrifuge Types & Models

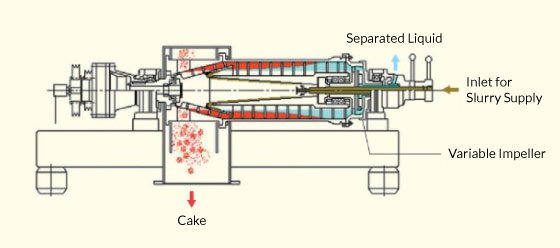

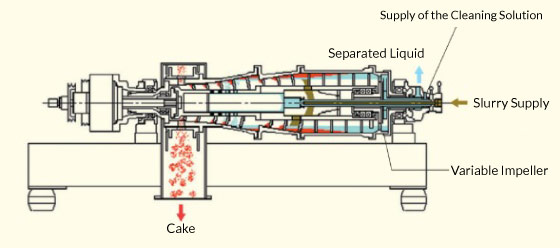

As an authorised TANABE WILLTEC partner and distributor, we provide reliable industrial centrifuge solutions tailored to industry needs. Our TANABE Decanter Centrifuges are available in specialized models, each engineered to handle different slurry types and separation challenges:

Specialized Models for Unique Applications

In addition to standard models, TANABE also offers specialised decanter centrifuges designed to meet specific process requirements. These solutions are proven across industries, including food and beverage, palm oil processing, pharmaceuticals and chemicals, recycling and environmental management, and wastewater treatment.