Industrial Separation Solutions

De-con Continuous Centrifuge

Industrial Separation Solutions

De-con Continuous Centrifuge

De-con Continuous Centrifuge: Stable & Efficient Solid–Liquid Separation

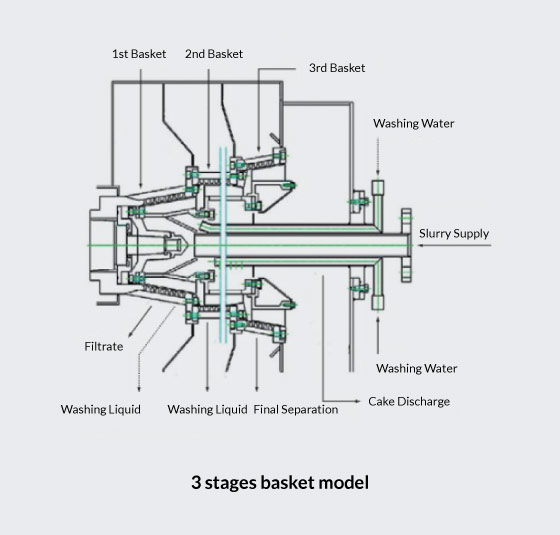

The De-con Continuous Centrifugation Model is designed for stable, continuous solid–liquid separation, delivering low moisture cake, high cake recovery, and effective cake washing. It is suitable for fine particles and viscous materials that are difficult to dehydrate using conventional filtration systems.

Key Functions & Features:-

Designed for efficiency, the system reduces processing time, facility footprint, and running costs. Mechanical vibration, installation area, and power consumption are minimized, while installation, operation, and maintenance are simplified. Despite its compact size, the model delivers high processing capacity.

Suitable for the following industry applications:

Technical Specifications

| Model | Basket Diameter (max mm) | Rotational Speed (min-1) | Centrifugal Effect (G) | Motor Power (kW) | Processing Amount (Slurry) (m³/h) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|---|

| MSC30-3 | 300 | 2700 | 1200 | 7.5 – 11 | 2 – 3 | 1500 | 1300 | 1100 |

| MSC45-3 | 450 | 2200 | 1200 | 15 – 22 | 3 – 6 | 2000 | 1700 | 1400 |

| MSC60-3 | 600 | 1700 | 1000 | 30 – 45 | 6 – 11 | 2500 | 2100 | 1750 |

| MSC80-3 | 800 | 1500 | 1000 | 55 – 75 | 11 – 18 | 3100 | 2550 | 2100 |