Dry Ice Ingot Production System

Sakura Dry Ice Station

Dry Ice Ingot Production System

Sakura Dry Ice Station

On-Demand Dry Ice Ingot Production in Kuala Lumpur, Malaysia

As a trusted partner for Sakura Seisakusho, PS Mechanical Supply & Services provides the Sakura Dry Ice Station to manufacturers, logistics operators, laboratories, and industrial users across Malaysia.

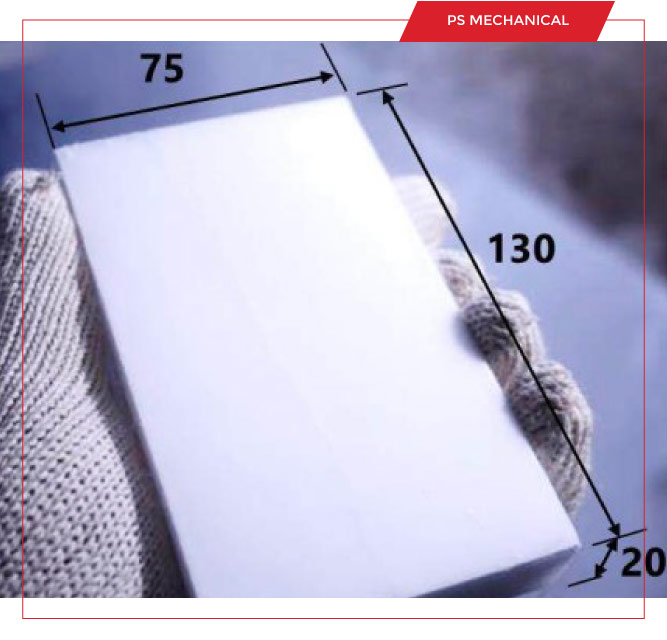

Sakura Dry Ice Station is an on-site dry ice ingot production system designed for companies that require a stable, immediate, and cost-controlled dry ice supply. Producing dry ice directly at your facility eliminates reliance on external suppliers while significantly reducing sublimation loss. Powered by Sakura Seisakusho’s proven press mechanism, the system delivers high conversion efficiency, consistent ingot quality, and reliable output, making it suitable for continuous industrial use.

When Do You Need a Dry Ice Station?

Experience losses due to dry ice sublimation

Use dry ice frequently or daily

Require immediate and reliable dry ice supply

Want better cost control and operational flexibility

Dry Ice Station vs Purchased Dry Ice Supply

| Criteria | Purchased Dry Ice Supply | Sakura Dry Ice Station |

|---|---|---|

| Production method | Delivery-based supply from external vendors | On-site dry ice production |

| Availability | Dependent on supplier schedule | Immediate, on-demand production |

| Sublimation loss | High loss during transport and storage | Significantly reduced due to on-demand use |

| Operational control | Limited control over quantity and timing | Full control over production volume and timing |

| Cost predictability | Recurring and variable purchasing costs | More stable long-term operating costs |

| Peak demand readiness | Risk of shortage during high demand | Always available when required |